1. Essential Roles and Functional Goals in Concrete Modern Technology

1.1 The Objective and Device of Concrete Foaming Agents

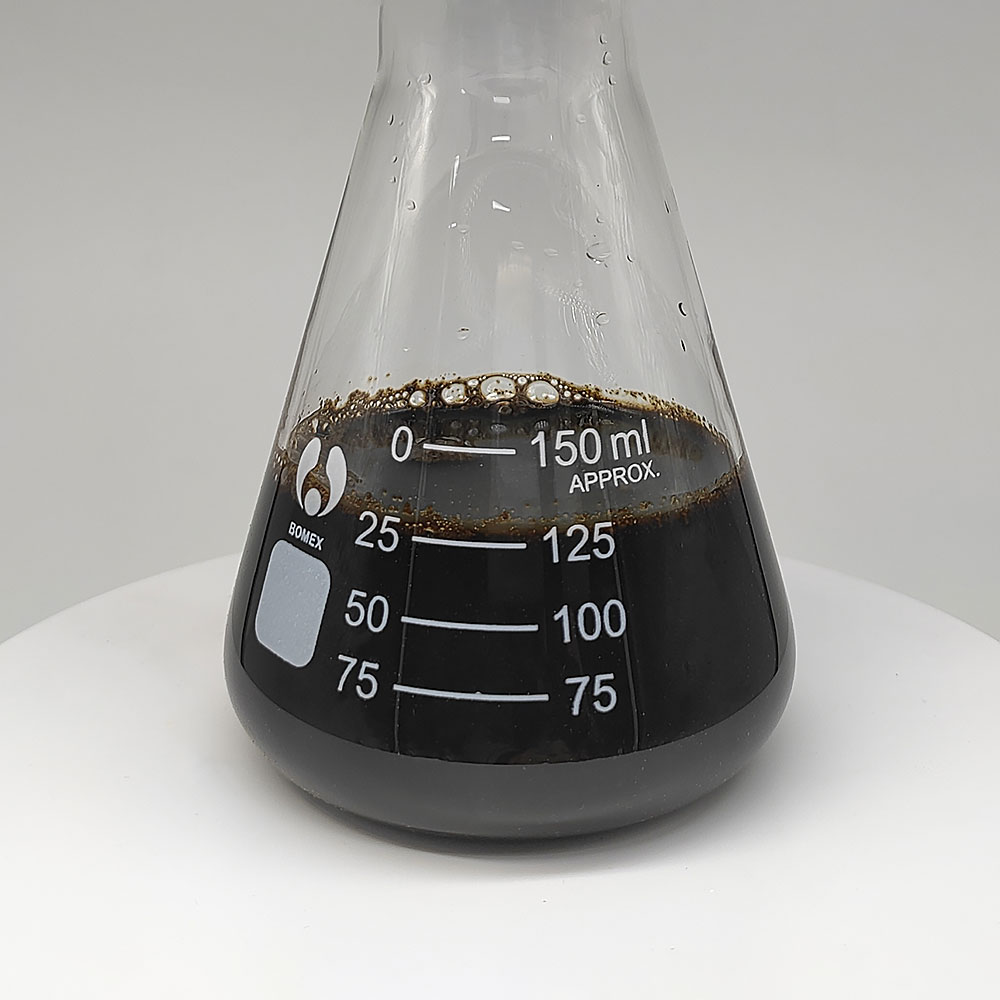

(Concrete foaming agent)

Concrete foaming agents are specialized chemical admixtures created to intentionally introduce and maintain a regulated volume of air bubbles within the fresh concrete matrix.

These representatives function by minimizing the surface area tension of the mixing water, enabling the formation of fine, consistently distributed air spaces throughout mechanical frustration or mixing.

The primary objective is to produce cellular concrete or lightweight concrete, where the entrained air bubbles significantly minimize the total thickness of the hard material while maintaining sufficient structural integrity.

Foaming representatives are commonly based on protein-derived surfactants (such as hydrolyzed keratin from pet by-products) or artificial surfactants (including alkyl sulfonates, ethoxylated alcohols, or fat derivatives), each offering distinctive bubble stability and foam framework attributes.

The produced foam needs to be steady enough to endure the mixing, pumping, and initial setting phases without extreme coalescence or collapse, ensuring an uniform mobile structure in the final product.

This crafted porosity boosts thermal insulation, minimizes dead lots, and boosts fire resistance, making foamed concrete suitable for applications such as insulating floor screeds, void filling, and premade lightweight panels.

1.2 The Function and Mechanism of Concrete Defoamers

In contrast, concrete defoamers (additionally known as anti-foaming agents) are formulated to remove or decrease unwanted entrapped air within the concrete mix.

Throughout blending, transportation, and placement, air can end up being unintentionally entrapped in the concrete paste due to anxiety, particularly in very fluid or self-consolidating concrete (SCC) systems with high superplasticizer web content.

These allured air bubbles are usually uneven in size, badly distributed, and destructive to the mechanical and aesthetic homes of the hardened concrete.

Defoamers work by destabilizing air bubbles at the air-liquid interface, promoting coalescence and rupture of the slim liquid films surrounding the bubbles.

( Concrete foaming agent)

They are commonly composed of insoluble oils (such as mineral or veggie oils), siloxane-based polymers (e.g., polydimethylsiloxane), or strong bits like hydrophobic silica, which penetrate the bubble film and speed up water drainage and collapse.

By lowering air content– typically from problematic degrees over 5% down to 1– 2%– defoamers enhance compressive stamina, improve surface coating, and boost resilience by decreasing leaks in the structure and potential freeze-thaw susceptability.

2. Chemical Composition and Interfacial Habits

2.1 Molecular Design of Foaming Representatives

The effectiveness of a concrete frothing representative is very closely linked to its molecular structure and interfacial activity.

Protein-based lathering agents count on long-chain polypeptides that unravel at the air-water user interface, forming viscoelastic movies that resist tear and give mechanical strength to the bubble walls.

These all-natural surfactants produce fairly huge however secure bubbles with excellent perseverance, making them ideal for structural lightweight concrete.

Artificial foaming agents, on the other hand, deal greater uniformity and are less sensitive to variants in water chemistry or temperature level.

They develop smaller, more uniform bubbles because of their reduced surface stress and faster adsorption kinetics, resulting in finer pore structures and improved thermal performance.

The crucial micelle focus (CMC) and hydrophilic-lipophilic equilibrium (HLB) of the surfactant establish its effectiveness in foam generation and security under shear and cementitious alkalinity.

2.2 Molecular Design of Defoamers

Defoamers operate through a basically different system, depending on immiscibility and interfacial incompatibility.

Silicone-based defoamers, specifically polydimethylsiloxane (PDMS), are very reliable as a result of their very low surface area stress (~ 20– 25 mN/m), which enables them to spread out swiftly across the surface of air bubbles.

When a defoamer droplet contacts a bubble movie, it produces a “bridge” between the two surface areas of the movie, causing dewetting and tear.

Oil-based defoamers operate in a similar way but are much less reliable in highly fluid blends where fast dispersion can weaken their activity.

Crossbreed defoamers including hydrophobic bits improve performance by supplying nucleation websites for bubble coalescence.

Unlike lathering representatives, defoamers have to be sparingly soluble to stay energetic at the user interface without being incorporated into micelles or liquified into the mass phase.

3. Effect on Fresh and Hardened Concrete Residence

3.1 Impact of Foaming Representatives on Concrete Performance

The purposeful introduction of air via foaming agents transforms the physical nature of concrete, shifting it from a dense composite to a porous, light-weight product.

Thickness can be lowered from a normal 2400 kg/m Âł to as low as 400– 800 kg/m TWO, depending on foam quantity and stability.

This reduction directly associates with reduced thermal conductivity, making foamed concrete a reliable protecting product with U-values appropriate for constructing envelopes.

However, the enhanced porosity additionally leads to a decrease in compressive toughness, necessitating mindful dosage control and often the addition of additional cementitious products (SCMs) like fly ash or silica fume to improve pore wall strength.

Workability is typically high because of the lubricating result of bubbles, however segregation can occur if foam stability is poor.

3.2 Influence of Defoamers on Concrete Efficiency

Defoamers enhance the quality of conventional and high-performance concrete by getting rid of issues triggered by entrapped air.

Excessive air gaps act as stress and anxiety concentrators and decrease the effective load-bearing cross-section, resulting in reduced compressive and flexural toughness.

By minimizing these spaces, defoamers can boost compressive strength by 10– 20%, specifically in high-strength mixes where every quantity portion of air issues.

They likewise enhance surface top quality by stopping pitting, pest openings, and honeycombing, which is critical in architectural concrete and form-facing applications.

In impermeable frameworks such as water storage tanks or basements, lowered porosity boosts resistance to chloride access and carbonation, extending life span.

4. Application Contexts and Compatibility Considerations

4.1 Common Usage Situations for Foaming Agents

Foaming representatives are important in the manufacturing of cellular concrete used in thermal insulation layers, roofing system decks, and precast light-weight blocks.

They are likewise utilized in geotechnical applications such as trench backfilling and gap stabilization, where low density avoids overloading of underlying dirts.

In fire-rated settings up, the protecting buildings of foamed concrete provide passive fire defense for structural components.

The success of these applications depends on specific foam generation devices, secure foaming representatives, and appropriate blending treatments to make sure uniform air circulation.

4.2 Normal Use Instances for Defoamers

Defoamers are generally made use of in self-consolidating concrete (SCC), where high fluidity and superplasticizer material boost the threat of air entrapment.

They are likewise essential in precast and building concrete, where surface area coating is vital, and in undersea concrete positioning, where entraped air can endanger bond and resilience.

Defoamers are usually included tiny dosages (0.01– 0.1% by weight of concrete) and must work with various other admixtures, specifically polycarboxylate ethers (PCEs), to prevent damaging interactions.

In conclusion, concrete lathering representatives and defoamers stand for two opposing yet just as vital approaches in air monitoring within cementitious systems.

While frothing agents intentionally present air to accomplish lightweight and protecting properties, defoamers get rid of undesirable air to boost toughness and surface quality.

Understanding their distinctive chemistries, devices, and effects allows designers and manufacturers to enhance concrete efficiency for a vast array of structural, functional, and visual needs.

Distributor

Cabr-Concrete is a supplier of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high quality Concrete Admixture, please feel free to contact us and send an inquiry.

Tags: concrete foaming agent,concrete foaming agent price,foaming agent for concrete

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us