Introduction to Concrete Foaming Representative

Concrete lathering agents are playing an increasingly crucial duty in modern-day construction by making it possible for the production of lightweight, durable, and extremely insulative concrete materials. These agents introduce air bubbles right into the concrete mix, minimizing its density while keeping structural stability. This post explores the special residential properties, applications, and future capacity of concrete frothing representatives.

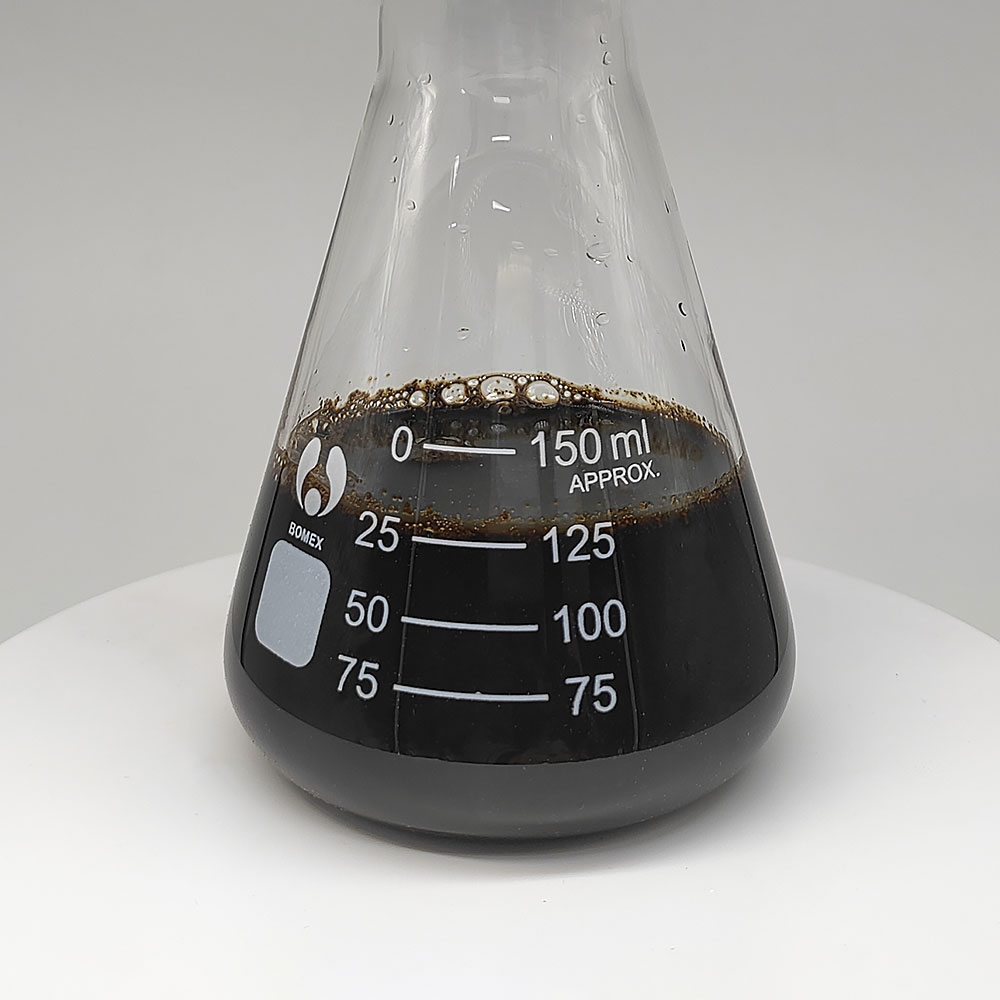

(Concrete foaming agent)

Make-up and Production Process

Concrete frothing representatives are normally made from synthetic or natural surfactants that can maintain air bubbles within the concrete matrix.

The manufacturing procedure includes mixing these surfactants with water to develop a steady foam. This foam is then combined right into the concrete mixture before putting. The resulting aerated concrete deals improved thermal insulation and lowered weight contrasted to conventional concrete. The capability to regulate the dimension and circulation of air bubbles guarantees consistent efficiency across different applications.

Applications Across Different Sectors

Concrete lathering agents locate substantial usage throughout multiple industries due to their versatility and advantages. In household and business construction, they are used to create light-weight cinder block and panels that minimize building load and boost power effectiveness. Civil engineering projects take advantage of foamed concrete’s capability to fill voids and maintain soil without including significant weight. Furthermore, precast concrete producers make use of lathering agents to generate elements with improved acoustic and thermal properties. Each field leverages the one-of-a-kind advantages of foamed concrete for much better efficiency and expense savings.

Market Fads and Development Drivers

The demand for concrete lathering agents is growing alongside the raising need for lasting and reliable structure materials. Developments in formulation modern technology have improved the security and longevity of foamed concrete. Rigorous testing ensures that items fulfill market requirements, leading to higher-quality offerings. Business embracing these technologies offer superior services. Customer understanding concerning the benefits of making use of foamed concrete, such as reduced transportation costs and lowered ecological effect, drives market interest. Advertising and marketing initiatives focus on enlightening customers concerning the benefits of these sophisticated products.

Challenges and Limitations

One significant challenge with concrete frothing representatives is making certain consistent quality during large-scale manufacturing. Irregularity in raw materials and environmental conditions can impact foam stability and concrete performance. One more concern is the preliminary cost, which might be greater than standard concrete approaches. Nonetheless, the long-lasting benefits usually exceed the costs. Products made with foaming agents last longer and carry out far better. Business should demonstrate the worth of these representatives to warrant their use. Research study continues to address these difficulties, aiming to improve sustainability and efficiency. Clear communication regarding the advantages builds trust amongst customers and regulatory authorities.

Future Prospects: Technologies and Opportunities

The future looks guaranteeing for concrete frothing representatives with continual study targeted at improving their buildings and expanding applications. Developments include establishing much more green formulations and checking out brand-new usages in arising innovations. As markets seek even more sustainable and effective services, concrete frothing agents will remain vital. Their capability to give lightweight, long lasting, and insulative products makes them important. New advancements might open extra applications, driving additional development and advancement.

End of Paper

( Concrete foaming agent)

This detailed exploration of concrete foaming representatives highlights their relevance and possibility in contemporary building and construction techniques. By focusing on useful applications and future chances, the write-up intends to give readers with a thorough understanding of this innovative product. The title and web content are developed to involve experts and lovers alike, stressing both deepness and relevance in the conversation of concrete frothing representatives.

Supplier & ^ ..

Cabr-Concrete is a supplier under TRUNNANO of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for Concrete foaming agent, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

Tags: concrete foaming agent,concrete foaming agent price,foaming agent for concrete

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us